HIGH-TECHNOLOGY PALLETS WITH RFID CHIPS

Keeping up with the times, keeping ahead of the competition, and saving money by choosing high-technology solutions. This is what large manufacturers and logistics companies, which choose pallets with RFID chips (tags) for fields such as internal logistics and transportation, are targeting today, in times of crisis.

Technology of radio-frequency identification (RFID)

The technology of radio-frequency identification (RFID) offers many advantages in the fields of transportation, storage, and internal logistics: effective accounting, clear identification of packaging and cargo, accelerated receipt of goods, the possibility of continuous monitoring. Unlike usual labels containing barcodes, RFID chips (tags) can contain significantly more information, which can be read very easily.

High-technology solutions that facilitate work

The KRONUS competence lies in the creation of complex high-technology products. The demand for using RFID technology for packaging in fields such as production and logistics is growing rapidly, because such equipment enables companies to save their main resources, which are time and money, necessary for monitoring and accounting related to products and packaging. By inserting RFID chips (tags) into pallets, KRONUS offers its customers not just packaging, but modern, high-technology packaging solutions where data storage devices are used.

Advantages

It is estimated that, despite the costs associated with purchasing and installing RFID equipment, the use of this technology brings savings. By using and evaluating the data contained in the RFID chip (tag), users can purposefully optimise individual processes and, ultimately, the entire value chain, which, as a result, makes these processes more economical. In addition, RFID chips (tags) increase the accuracy of accounting related to packaging, reduce pallet losses, and make it possible to track the location of the cargo during transportation.

- Process optimisation

- Savings

- Accuracy of accounting related to packaging

- Control of goods

Pallets with RFID chips (tags)

During production, each pallet is equipped with a unique RFID chip (tag), an identification device containing a specific data set, which makes the processes of loading, storage, of internal logistics with regard to workshops and warehouses, as well as those of deliveries simpler and reliable – and these processes take place in a controlled way.

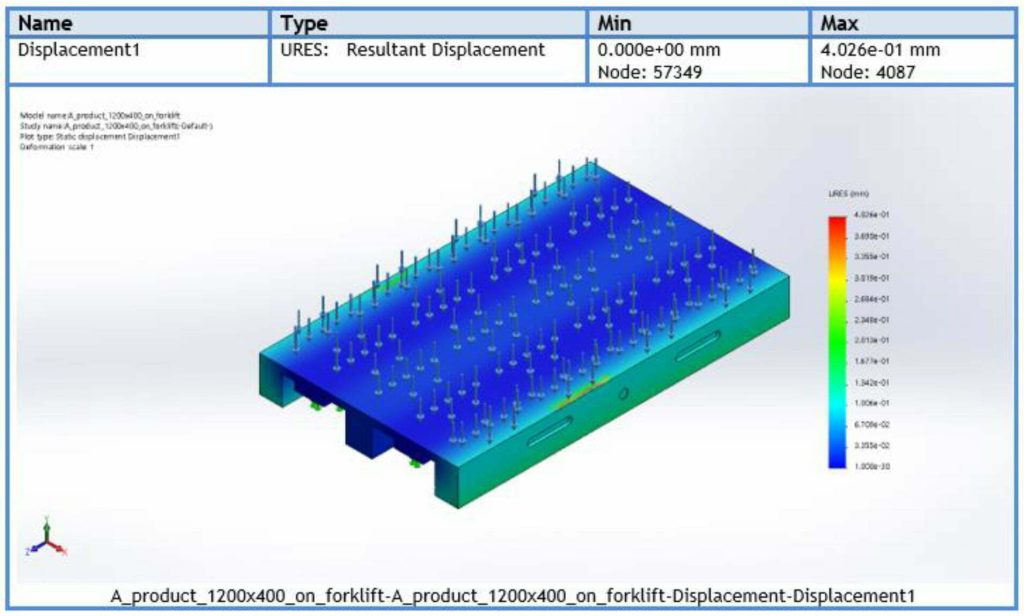

Strength and loading capacity

When manufacturing pallets with RFID chips (tags), KRONUS takes into consideration the parameters of the cargo that the customer plans to place on pallets. Before showing the product to the customer, the company carries out tests, including the simulation of loads, as well as the simulation regarding the deformation of a pallet on a rack, a loader, and a line designed for moving goods.

Uses of pallets with RFID chips (tags)

To date, pallets with RFID chips (tags) are most popular in fields such as internal logistics in large industries, during cargo transportation, in warehouses, as well as in retail.

- Logistics

Pallets with RFID chips (tags) make it possible to speed up the loading and unloading of goods, track cargo movement, monitor packaging turnover, and minimise employee errors.

- Manufacture

Pallets with RFID chips (tags) are widely used at production sites, in the field of internal logistics, which makes it possible to automate many processes, minimise possible employee errors, improve accounting related to packaging and parts, as well as to speed up processes.

- Retail

Pallets with RFID chips (tags) can be used in the field of retail to track the movement of goods in the store, as well as their movement out of the warehouse and into the store.